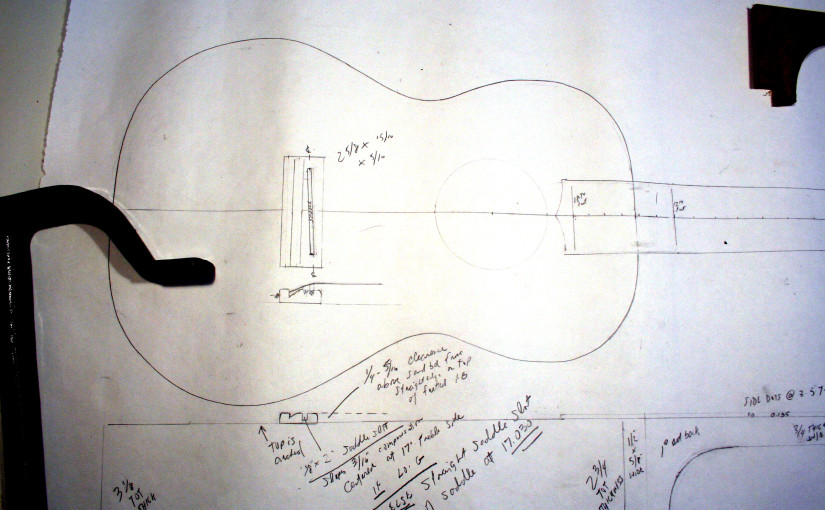

This tenor uke is being made out of Vermont black walnut for the back and sides, western red cedar for the top with sitka spruce braces, and spanish cedar neck, with koa headstock veneer and bubinga finderboard and bridge. Black walnut bends very nicely in addition to its other nice qualities.

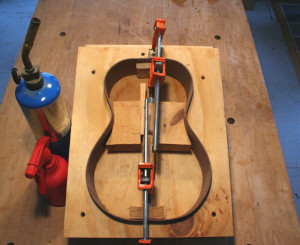

Side bending is done using a heated pipe, in this case a section of small sailboat mast. Woods bends by compression and not stretching, so it is important when bending to apply steady gentle pressure as the wood heats up, while supporting the outside of the bend. The picture below shows the torch heating the pipe, one side bent and in the body mold and the other side starting to be bent, checking the bend at the waist. Water from a spray bottle helps the heat transfer. After the sides are bent, they are placed in the mold to set.

After the sides are bent, they are placed in the mold to set.

The neck and tail blocks get glued in, the neck block slotted for the tenon of the neck. The tailblock is spruce, grain running parallel to the grain of the sides. The kerfed lining is installed next, while the top and back are made up.

Dimensions of the top and back finish out around 0.075″, which is just a little over 1/16″ thick. Not much! The top soundhole is cut out with a Dremel tool rotating around a pin centered in the soundhole, and the inside of the cut is lined with a piece of black fiber purfling to protect the end grain. The top bracing somewhat follows typical guitar X-bracing – but simpler.

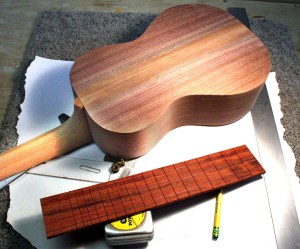

The back is glued on first, with the sides in the body mold, then the top is glued on and everything given a preliminary sanding.

The neck blank is made up out of 3 pieces of flatsawn cedar such that the result places the grain perpendicular to the pull of the strings. After gluing on the headstock veneer, the neck is rough carved and the tenon of the neck fitted to the body for the correct angle – This angle will place a line which follows the top of the fretted fingerboard such that it passes just over the top of the bridge (not the saddle). Here is a view of the back of the uke and next is a picture of the top. Both pictures show the beginning of the fingerboard, which is made out of African bubinga. The board will be tapered in width from the nut to the body (taper not cut yet), and is tapered in thickness from the nut to the body to give the required angle described above. Here is a top view, showing the neck tenon and top. Stay tuned for updates.

next is a picture of the top. Both pictures show the beginning of the fingerboard, which is made out of African bubinga. The board will be tapered in width from the nut to the body (taper not cut yet), and is tapered in thickness from the nut to the body to give the required angle described above. Here is a top view, showing the neck tenon and top. Stay tuned for updates.