First, a disclaimer – my object in building this canoe is to honor the skill and aesthetic standards of the builders who originated these boats and the methods they perfected of building them. Although I have developed my ‘own’ set of lines, they are based on boats built by others – Dale Tobey in particular. My design, which I hope will be successful, will never be a ‘Grand Laker’ – but it will be a Grand Laker-type which closely models boats I measured in Maine that originated in Grand Lake. My thanks and respect go to the builders who have helped me with information and construction tips, including Jerry Stelmok and Rolin Thurlow, and Dale Tobey by way of pictures he has posted of his boats, and his comments on the WCHA site.

The form stations assembled on a 2×8 plank backbone with 2×4 outer members taking a lot of care to assure everything was level and plumb. The stations are glued and screwed into dadoes cut in the backbone.

The first of the 7/8″ x 1 1/8″ pine sheathing strips went on about 8″ below and parallel to the gunwale. Shorter strips that were manageable to saw were joined with glued and screwed butt-blocks to make up the 19′ strips needed. In the picture below, the stem form has not yet been added.

Working towards the bottom – each strip glued and screwed to the frame and glued and nailed to its neighbor with 2″ air-gun finish nails.

Stern view

It was very exciting to see the shape develop smoothly with a few exceptions that were addressed by shimming three stations – watching for unfairness as the strips went on clearly showed where I needed to correct the offsets, which in retrospect were evident in the lines of my body plan. The table of offsets previously posted has been corrected accordingly.

Storing and moving the form around – how to? I found this picture posted by Weatherby’s of a Pop Moore boat on its form – the form has a wheeled undercarriage. Great idea.  I did the same. Below, the form before fairing and adding the metal bands.

I did the same. Below, the form before fairing and adding the metal bands.

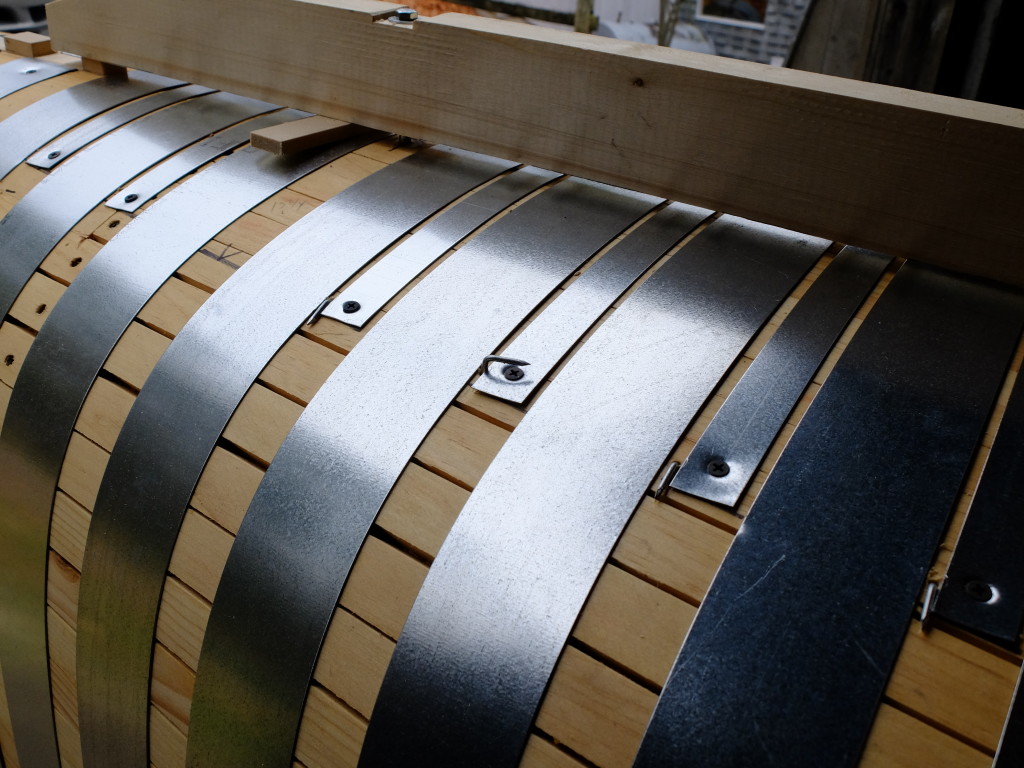

After (2 days of) fairing the form. Coated with boiled linseed oil thinned with mineral spirits. Below – with backup bands for ribs, 2 1/2″ 20 gauge galv. steel, 4″ on center. This form will have half-ribs through the bottom, with backup bands 1″ wide, yet to be added.

After (2 days of) fairing the form. Coated with boiled linseed oil thinned with mineral spirits. Below – with backup bands for ribs, 2 1/2″ 20 gauge galv. steel, 4″ on center. This form will have half-ribs through the bottom, with backup bands 1″ wide, yet to be added.

The stem – 1″ square ash, fresh cut from a green log – on the bending form

The steam rig – a propane hotplate, an old kettle, a piece of radiator hose and a pine box – I let the stem steam for an hour and it bent with careful pressure.

The steam rig – a propane hotplate, an old kettle, a piece of radiator hose and a pine box – I let the stem steam for an hour and it bent with careful pressure.

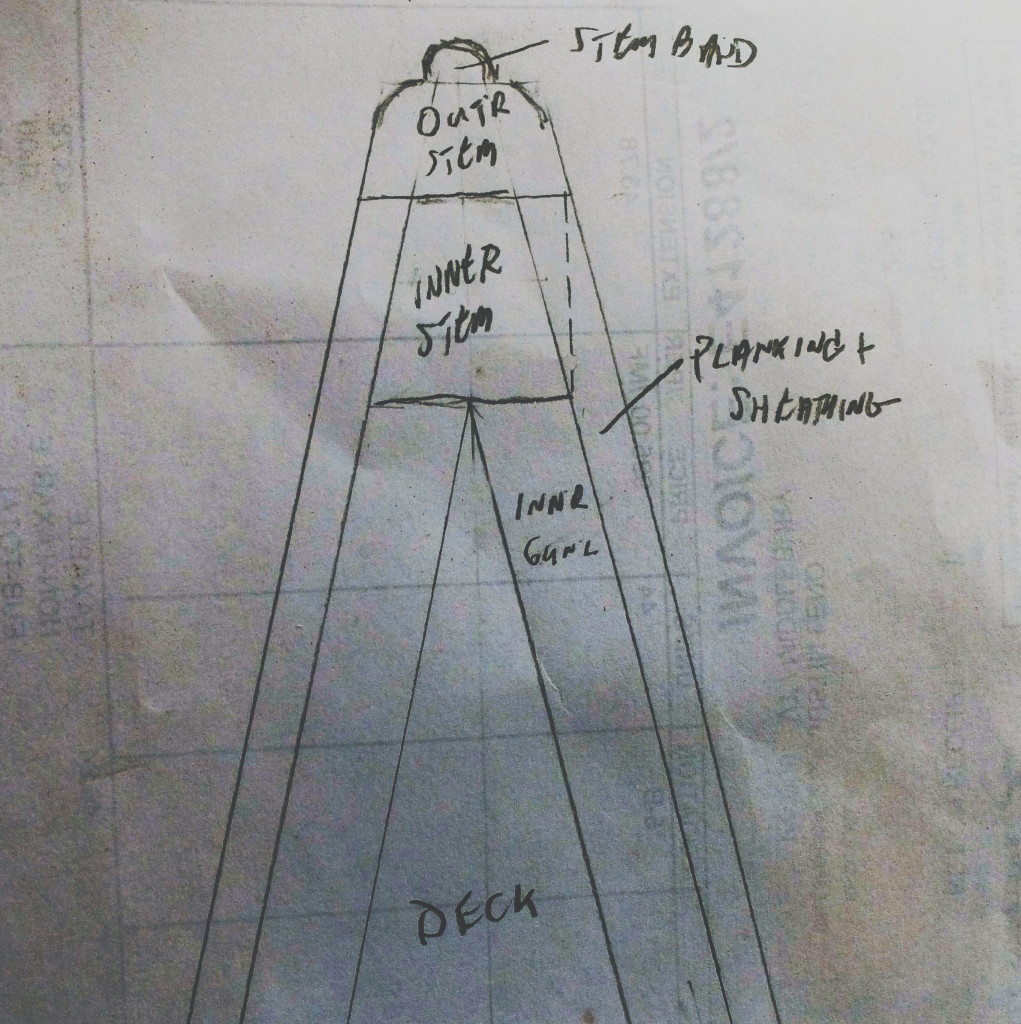

Inner gunwales are spruce, 1″ x 1 1/8″ – very hard to find clear pieces 21 feet long. These were cut from a 2×12 – 22′ found at the local lumber yard. I got enough material for both inner and outer gunwales. The upsweep at the stem is strong enough to require steaming and pre-bending the last 3′ of the gunwales in a jig. They taper to 1/2″ wide x 3/4″ tall at the stem. The stem layout – The inner gunwales will butt up behind the inner stem and attach to the stem with a small knee. The inner gunwale gets clamped to the gunwale backer on the form so it sits vertical, and has to be tapered on its outside face for the flare in the forward sections of this boat, as well as the tumblehome in the after sections. This, so the ribs will have good contact where they are nailed to the gunwale. The transom on this boat is black walnut, with a rabbet cut in its outside face for the fold of the fiberglass sheathing to sit in, and is notched for the gunwales. The form

The inner gunwale gets clamped to the gunwale backer on the form so it sits vertical, and has to be tapered on its outside face for the flare in the forward sections of this boat, as well as the tumblehome in the after sections. This, so the ribs will have good contact where they are nailed to the gunwale. The transom on this boat is black walnut, with a rabbet cut in its outside face for the fold of the fiberglass sheathing to sit in, and is notched for the gunwales. The form now has the backer bands for the half ribs which will be held in place initially by #6 box nails bent up through the form. The half ribs will help offset the tendency of the main ribs to spring back into a rounder shape than the hull form – I want a semi-flat bottom section. The strongback is bolted through the form to T-nuts inside. When bending the ribs, it will hold the middle of the rib down and prevent things from shifting around until the planking goes on. The form is now ready for the ribs to be bent and nailed to the inner gunwale.

now has the backer bands for the half ribs which will be held in place initially by #6 box nails bent up through the form. The half ribs will help offset the tendency of the main ribs to spring back into a rounder shape than the hull form – I want a semi-flat bottom section. The strongback is bolted through the form to T-nuts inside. When bending the ribs, it will hold the middle of the rib down and prevent things from shifting around until the planking goes on. The form is now ready for the ribs to be bent and nailed to the inner gunwale.