I now have four years experience with this boat. We have just come back from a camping trip where we had a lot of stony landings. In total we have probably dragged the boat ashore and launched over a 100 times since it was new, and I thought I needed to check the condition of the bottom to see how much damage had been done. This boat is the one described in the earlier blog entries, the exterior finished with a double layer of fiberglass cloth set in epoxy. I have built several cedar/canvas canoes with the traditional filled canvas covering, and the Grand Laker type canoes are in the same line; however, all the current builders of lakers I have talked to now use fiberglass because of its toughness, and I followed their example. I am well aware of the deviation from the traditional approach. I still run into other boaters who see fiberglass on a cedar canoe and say ‘big mistake’. I therefore want to give a brief report on the condition of my boat after 4 years of use and reiterate the reasons why I think fiberglass is a good choice.

This is the beach at our campsite. It is made up of coarsely rounded gravel averaging about 1/4″ in diameter, and we dragged the boat on and off the beach at least 3 times a day. This was the smoothest landing we had during this trip; others consisted of sharply angular fill, and a couple were unusable altogether. We didn’t hit any rocks in the water, but that could have happened. We are not young people and when it comes to choosing between letting the boat take the knocks, and us struggling with it, the boat has to look after itself. Fully loaded, we are carrying about 750 pounds of boat, motor, gear and people, and some of the landings happen with a loaded boat. I came home working on a plan to repair what I thought would be significant gouges in the fiberglass. I was pretty certain that, had the boat been covered with canvas, I would be dealing with rips and tears.

My repair plan was to sand the bottom of the boat back to bare epoxy, put on a thin new epoxy coat to fill the scratches and seal any fiberglass exposed, and repaint. What I found was that the bottom is still sound. The paint is worn where the boat is grounded out, the only scratches approaching any kind of need for attention came from earlier trips where we had hit rocks on the move while loaded. But nothing needs to be repaired at this time.

This is the bottom of the stem. The keel projects 3/4″ and is capped with a brass band for about two feet back from where it enters the water and is effectively doing its job of taking the brunt of the landings while protecting the fiberglass skin. The stem itself is made of white ash, and the keel is white oak.

This is a little further aft; the keel widens from 3/4″ where it is scarfed to the stem, to about 3″ amidships, and then tapers back to 2″ at the transom. Again, the keel is taking the hits, some of the bottom paint is scratched but not gouged.

Approaching midship.

Aft of center, showing the scarf in the keel where most of the weight sits when grounded. Keel a little worn but intact, large scratch from hitting a rock while moving, but nothing to worry about.

A little further aft.

So – I am happy with the performance of the fiberglass and paint. The advantages as I see them of fiberglass are :

- It adds considerable strength and rigidity to the hull. I have no problem with oil-canning, I think partly thanks to the fiberglass/epoxy. Canvas would not add as much strength.

- The strength helps absorb the stresses of trailering and chaffing on the trailer / tie-downs.

- There is no space between the planking and covering in which sand can accumulate, as it can with a canvas-covered boat where sands works down from the inside if there are any gaps between planks.

- It does not rip like canvas, nor is there any concern about rot.

- It can cover a width of beam that is difficult to find canvas big enough for on these 20′ boats.

- Fiberglass is no heavier and possibly lighter than filled canvas, and does not gain weight as it gets wet.

The disadvantages are all in the realm of could-be in the future :

- The epoxy prevents the planking from expanding on the outside, while the inside theoretically can expand, creating stresses that could possibly separate the epoxy from the planking, or crack the fiberglass along the plank seams. Maybe this would be a problem if you left the boat in the water for extended periods, but that is not how I use my boat. It is in the water for a few days, then back out and stored under cover. This problem can be mitigated by using quarter-sawn planking lumber that is properly dried.

- Replacement of rotted/broken ribs or planks becomes impossible with an epoxy skin, unlike canvas where you can take the whole think apart one tack at a time. True, but I don’t expect to break ribs or planks, and with care taken for how you store the boat, rot is unlikely. Conversely, repair of an epoxy-coated boat with structural damage can be accomplished with techniques used for repair of fiberglass boats, and presents no more difficulty, or rather is no easier, than structural repair of a strip-planked boat.

I have reached the point in my life where the question of who outlives who is no longer in doubt – unless something goes really well or really wrong, the boat will outlive me regardless of how the fiberglass wears. The boat below is fifteen years old and in need of a refinish – this particular design tends to hog pretty badly – but with a sanding, fresh filler epoxy coat, and some paint will be back in service as long as the owner wants it.

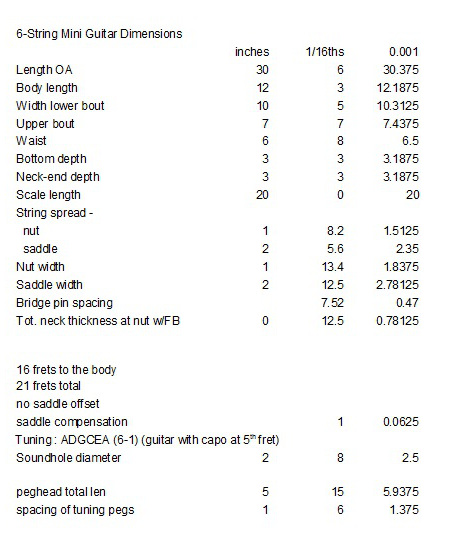

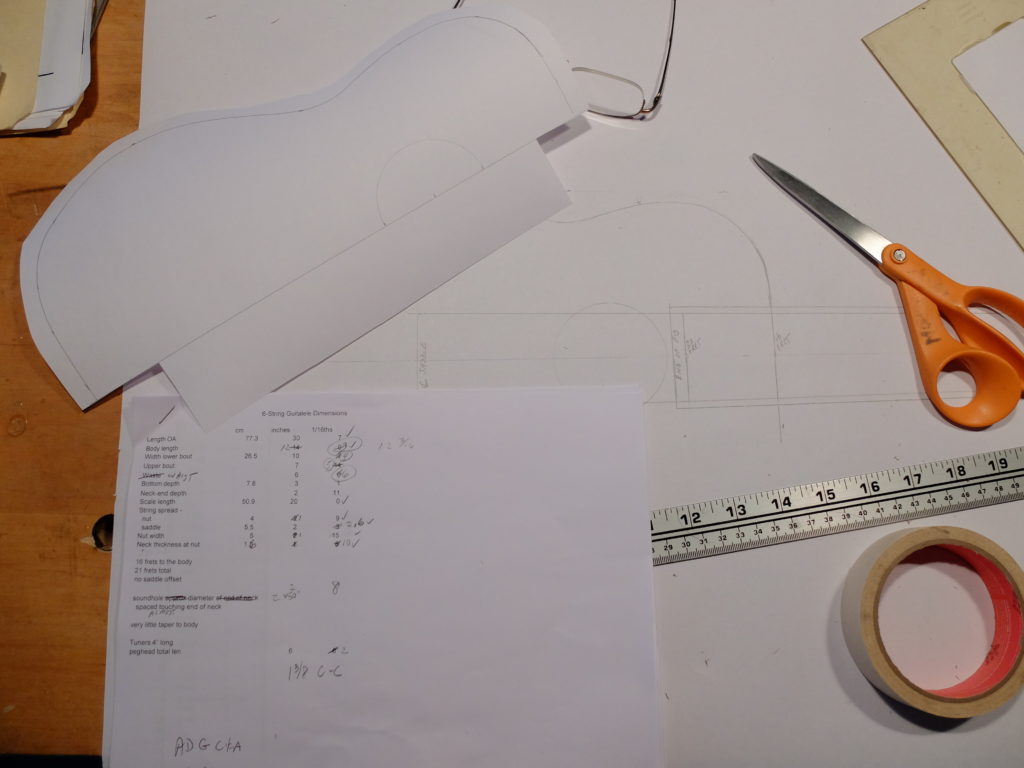

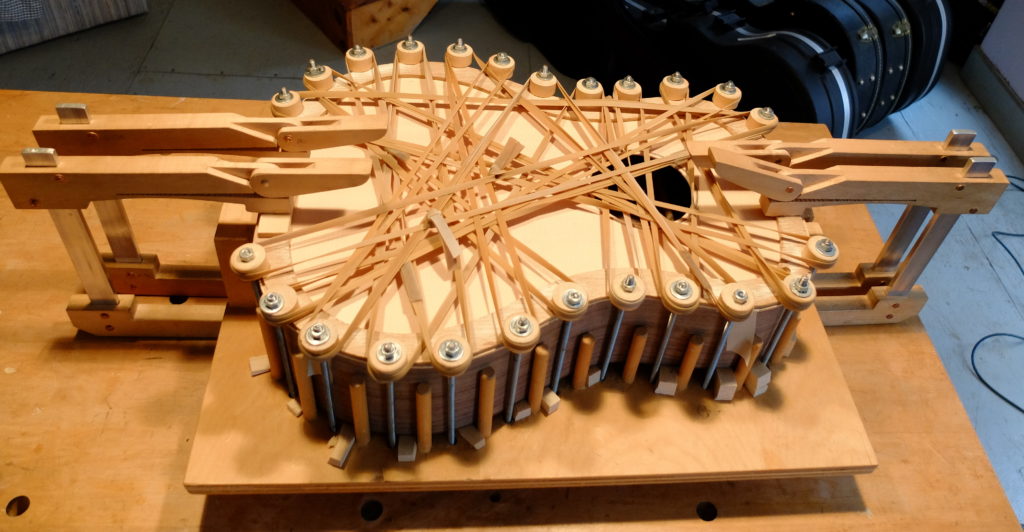

The neck blank came from a single piece of mahogany salvaged from a sailboat bowsprit, and is reinforced with a 1/8″ x 3/8″ carbon fiber rod. Below – the sides in the form with the back attached, showing the neck blank with koa peghead veneer and carbon fiber truss rod. I used a straight mortise and tenon bolt-on joint for the neck, using hanger bolts set in the heel of the neck to make the unlikely need for a neck reset easier. Mahogany neck block, spruce on the heel.

The neck blank came from a single piece of mahogany salvaged from a sailboat bowsprit, and is reinforced with a 1/8″ x 3/8″ carbon fiber rod. Below – the sides in the form with the back attached, showing the neck blank with koa peghead veneer and carbon fiber truss rod. I used a straight mortise and tenon bolt-on joint for the neck, using hanger bolts set in the heel of the neck to make the unlikely need for a neck reset easier. Mahogany neck block, spruce on the heel. The top is European spruce from a violin set finished to about 0.073″ thick. Since I planned on using a pinned guitar-style bridge, I put in a thin ebony (0.050″) bridge plate to take the ball-ends of the strings. My bracing was intended to provide resistance to torque on the top exerted by the bridge under tension, while giving some flexibility to the top in the area of the bridge, and uses a sort of elevated reduced-contact approach – the 2 main longitudinal braces contact the bridge but are elevated by about 3/32″ either side of it, contacting the top again at the heel and around the soundhole. The two cross braces above and below the soundhole do not contact the longitudinal braces, and the small finger braces below and to the sides of the bridge plate are semi-elevated also.

The top is European spruce from a violin set finished to about 0.073″ thick. Since I planned on using a pinned guitar-style bridge, I put in a thin ebony (0.050″) bridge plate to take the ball-ends of the strings. My bracing was intended to provide resistance to torque on the top exerted by the bridge under tension, while giving some flexibility to the top in the area of the bridge, and uses a sort of elevated reduced-contact approach – the 2 main longitudinal braces contact the bridge but are elevated by about 3/32″ either side of it, contacting the top again at the heel and around the soundhole. The two cross braces above and below the soundhole do not contact the longitudinal braces, and the small finger braces below and to the sides of the bridge plate are semi-elevated also.  Top glued on, binding on. The binding is black walnut with a black purfling strip.

Top glued on, binding on. The binding is black walnut with a black purfling strip. Two stages of carving the neck – after cutting the fingerboard taper (a little wide of the finished size), I cut the thickness taper and then establish 4 cross sections using a semi-circle template.

Two stages of carving the neck – after cutting the fingerboard taper (a little wide of the finished size), I cut the thickness taper and then establish 4 cross sections using a semi-circle template. Then it is fairly easy to join the sections

Then it is fairly easy to join the sections Quite a bit later – Strings are D’Addario Folk Nylon EJ34. I used Tru Oil for the finish, which allowed me to complete this instrument in a much shorter time than would have been possible with a normal oil varnish.

Quite a bit later – Strings are D’Addario Folk Nylon EJ34. I used Tru Oil for the finish, which allowed me to complete this instrument in a much shorter time than would have been possible with a normal oil varnish.

and cleverly filled it with concrete

and cleverly filled it with concrete only to discover I not only blocked the point of ingress, but also the point of egress. The interior mouse population apparently doubled. (that was the minor victory/disaster). In pursuit, things got a little out of hand after I decided I’d better check under the basement / guitar shop floor – to find all sorts of rot and corruption – insulation mouse-shredded, wet on the ground (it’s a dirt floor crawlspace under there), joists half rotted.

only to discover I not only blocked the point of ingress, but also the point of egress. The interior mouse population apparently doubled. (that was the minor victory/disaster). In pursuit, things got a little out of hand after I decided I’d better check under the basement / guitar shop floor – to find all sorts of rot and corruption – insulation mouse-shredded, wet on the ground (it’s a dirt floor crawlspace under there), joists half rotted.

The top braced and ready to glue – nicely quarted, fine grained Sitka spruce.

The top braced and ready to glue – nicely quarted, fine grained Sitka spruce. Gluing up the top – the rubber bands keep the spool clamps from slipping off the edge.

Gluing up the top – the rubber bands keep the spool clamps from slipping off the edge. First finish coats – de-waxed shellac sealer with oil varnish top coats. I used curly hard maple for the binding which contrasts nicely with the walnut.

First finish coats – de-waxed shellac sealer with oil varnish top coats. I used curly hard maple for the binding which contrasts nicely with the walnut. This is the archtop – sides bent, solid lining in (these are black cherry), neck and tail blocks in.

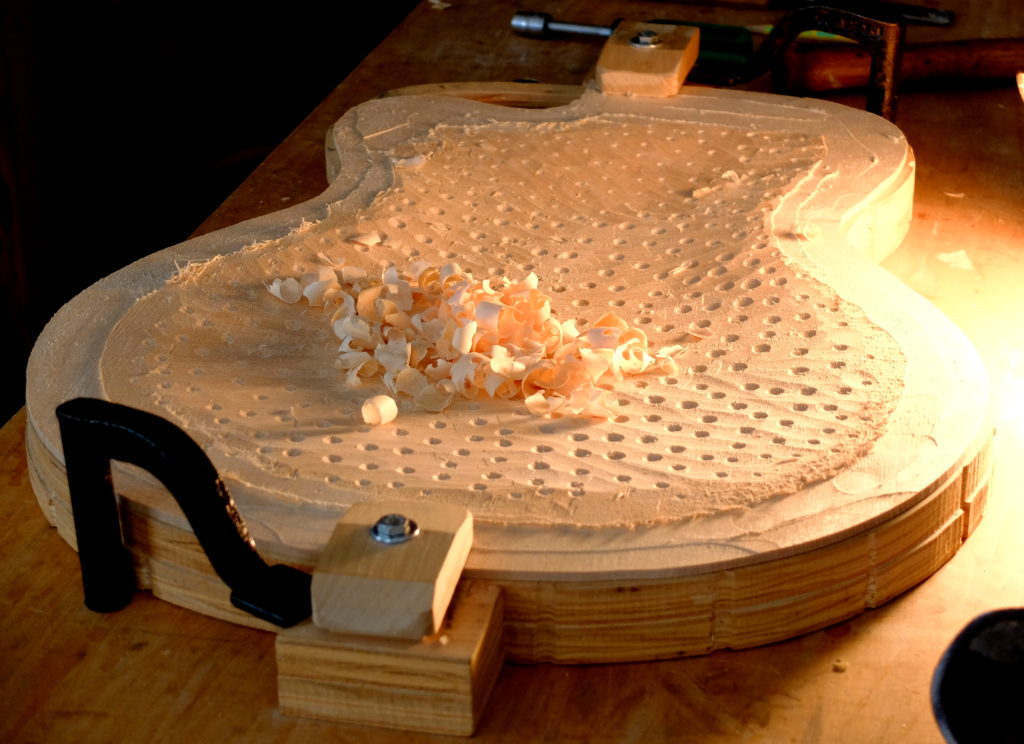

This is the archtop – sides bent, solid lining in (these are black cherry), neck and tail blocks in.  The back mid-carving – this is quilted big leaf maple with a curly hard maple center. Very slow going on the carving because of the hardness and interlocked grain of the maple – over 8 hours. After putting the outside profile on using templates, the inside is drilled on the drill press to a uniform depth and worked down to a thickness of 3/16″.

The back mid-carving – this is quilted big leaf maple with a curly hard maple center. Very slow going on the carving because of the hardness and interlocked grain of the maple – over 8 hours. After putting the outside profile on using templates, the inside is drilled on the drill press to a uniform depth and worked down to a thickness of 3/16″. The back ready to be glued on.

The back ready to be glued on. Glued on but not trimmed yet. It’s going to be very pretty.

Glued on but not trimmed yet. It’s going to be very pretty. The top mid-stream in carving which is where I left it to get a hip replacement. I’ll be able to resume work on it in a couple weeks.

The top mid-stream in carving which is where I left it to get a hip replacement. I’ll be able to resume work on it in a couple weeks.

I use wedges to hold the board in place for each cut. After all the slots are started, I mark the taper – 1 11/16″ at the nut to 2 3/16″ at the 14th fret – and then cut that out on the bandsaw and clean up the edges with the jointer after cutting the board to its finished length.

I use wedges to hold the board in place for each cut. After all the slots are started, I mark the taper – 1 11/16″ at the nut to 2 3/16″ at the 14th fret – and then cut that out on the bandsaw and clean up the edges with the jointer after cutting the board to its finished length.  Now is the time to do any inlay – this one has abalone dots at the octave position. I lightly glue (2 small drops of Titebond) the board to a flat, rigid backer, and start in with the radius sanding block with 80 grit paper. This is a flat top and uses a 16″ radius. I use rubber cement to glue the paper to the block.

Now is the time to do any inlay – this one has abalone dots at the octave position. I lightly glue (2 small drops of Titebond) the board to a flat, rigid backer, and start in with the radius sanding block with 80 grit paper. This is a flat top and uses a 16″ radius. I use rubber cement to glue the paper to the block. The radius goes on fairly quickly –

The radius goes on fairly quickly –  I make a series of pencil marks on the face, and when they are all gone, I can stop with that grit.

I make a series of pencil marks on the face, and when they are all gone, I can stop with that grit. When I have the whole board radiused, I stop and cut all the slots to their finished depth with the Stew Mac pull-stroke fret saw with depth attachment. I use a lubricant called Pro Cut to help keep the saw from binding. I shoot for cutting the slots at least 0.010″ deeper than the fret tang.

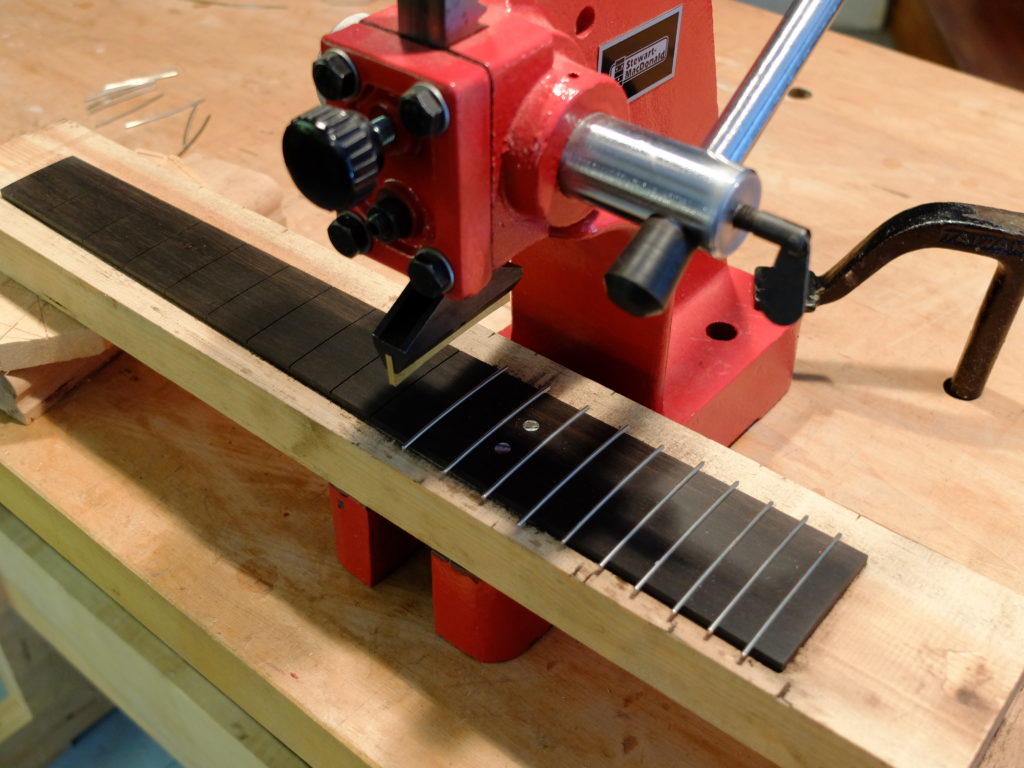

When I have the whole board radiused, I stop and cut all the slots to their finished depth with the Stew Mac pull-stroke fret saw with depth attachment. I use a lubricant called Pro Cut to help keep the saw from binding. I shoot for cutting the slots at least 0.010″ deeper than the fret tang. Now that I have the board radiused at 80 grit and the slots at their finished depth, I take the radius sanding block and work up through 120, 220, 400 and 600 grit successively, ending with a 0000 steel wool polish. This results in a semi-mirror finish ready for frets. I happen to use the Stew Mac fret press. You have to carefully line up the press caul with the fret to avoid tilting it, but pressed frets generally give a more uniform fretting job than hammered frets.

Now that I have the board radiused at 80 grit and the slots at their finished depth, I take the radius sanding block and work up through 120, 220, 400 and 600 grit successively, ending with a 0000 steel wool polish. This results in a semi-mirror finish ready for frets. I happen to use the Stew Mac fret press. You have to carefully line up the press caul with the fret to avoid tilting it, but pressed frets generally give a more uniform fretting job than hammered frets. After all the frets are in, they are snipped close to the edge and then a drop of Krazy Glue is applied to each fret end.

After all the frets are in, they are snipped close to the edge and then a drop of Krazy Glue is applied to each fret end. Next, I drill and put in the side dot markers – these are 1/16″, glued in with Krazy Glue.

Next, I drill and put in the side dot markers – these are 1/16″, glued in with Krazy Glue. Then the board is removed from the backer with a warm seam-separation knife (Stew Mac has one, if you don’t already), the ends of the frets are filed flush with the edge of the board and I’m ready to glue the board to the neck.

Then the board is removed from the backer with a warm seam-separation knife (Stew Mac has one, if you don’t already), the ends of the frets are filed flush with the edge of the board and I’m ready to glue the board to the neck.