Luke is making up a couple pedal boards – one, a road board for Guster touring, and a second for studio work. He wanted high-quality patch cables for the short jumps between pedals – eliminate troubleshooting intermittent outs on ten-pedal boards. He bought Mogami 2319 cable and the pancake head all-metal Switchcraft 228 jacks, and I offered to assemble them – 12 short patch cables in the case of the studio board. The 228 jacks have no lugs for the ground wire, and many people solder the ground directly to the jack body. The Mogami looked like regular patch cord wire – braided ground shield with center insulated conductor. The only thing I didn’t like was the Mogami measures less than the 0.210″ minimum diameter needed by the 228 to effectively hold the cable in the clamp – we added a layer of heat-shrink tubing at the clamp position to take care of that. I confidently assembled all 12 cables, soldering the grounds to the body and the hot to the jack tip. It was a complete surprise to find every one had either a dead short, or a weirdly partial short when I finished.

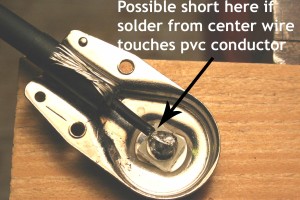

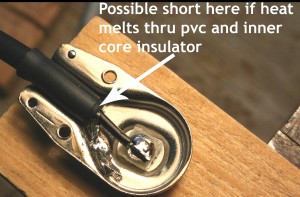

What I found out is the Mogami uses a pvc conductive shield under the braided ground wire, and over the hot wire insulator – the pvc shield can get shorted out to the hot by solder at the hot wire connection creating the partial short, which has the same effect as a volume pot on a low setting. And, the amount of heat needed to solder a ground to the jack body can very easily damage the insulator around the center hot wire, creating a dead short.

Had I checked the supplier website, Redco Audio, I would have seen the note that the pvc shield needs to be trimmed back. The solution was to trim back the pvc shield on the hot before soldering, and switch to a mechanical ground instead of a soldered ground. Still using the heat-shrink tubing to increase cable size for the clamp, the ground braid is folded back over the cable, half ‘on top’ and half ‘on the bottom’, and the hot is soldered to the hot lug of the jack – being careful to tin the jack lug before attempting to solder the hot wire. The finished connection looks like –