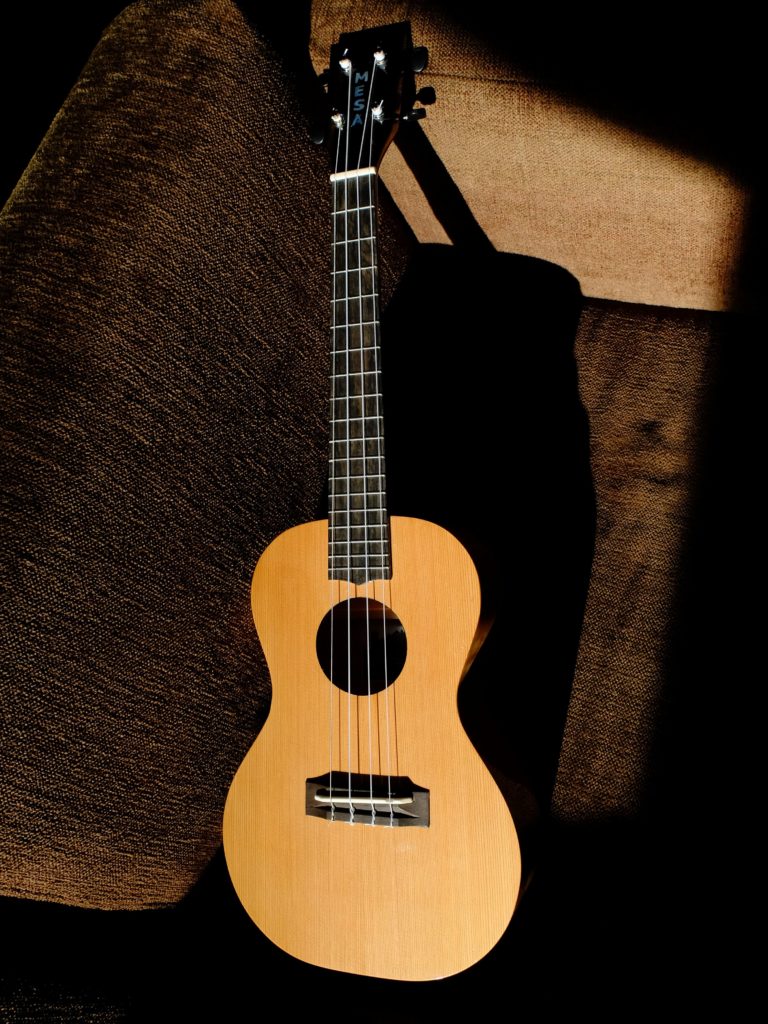

My grand daughter is showing signs of talent with guitar-family instruments, so I decided to make her a tenor uke for Christmas. Back and sides are quilted big leaf maple, around 0.070″ thick. Top is western red cedar, around 0.078″ thick, lightly braced, no bridge plate or anything like that. Solid linings 0.080″ thick to minimize reduction of resonant area on the top. Neck is spanish cedar, using a mortise and tenon neck joint, glued and bolted for good luck. Peghead, fingerboard and bridge are certified sustainably harvested second-grade ebony, and her name is inlaid in pearl. Peghead being readied for inlay –

Back and sides ready for glue-up

Top bracing complete – flat braces pass through cross brace without contact.

Finish is 10 coats of Tru Oil hand rubbed, sanded between coats 5 and 10, and rubbed out with Meguiars buffing compounds – complete in 3 days (Christmas rush).

I was excited to see her play it.